Start your Innovation Journey with us – let’s discover your perfect 3D printing powder together.

Your improvement potentialWe are your personal problem solver

Sustainability and innovation are in our DNA. Far from being recent trends, both are part of our established tradition. After all, we focus on the optimal use of resources and raw materials in every development – whether customised powder solutions for customers or in-house development of plants and processes.

As a long-term system and process partner, we are involved in our customers’ operations from the very beginning and know how their business works on the ground. Together we develop precisely the right powders.

Maybe soon for you too?

Set us a challenge!

Apply here for your free Innovation Journey

We solve your 3D printing problems before they arise – with our bespoke powder development. Call us, write to us – or visit us in person.

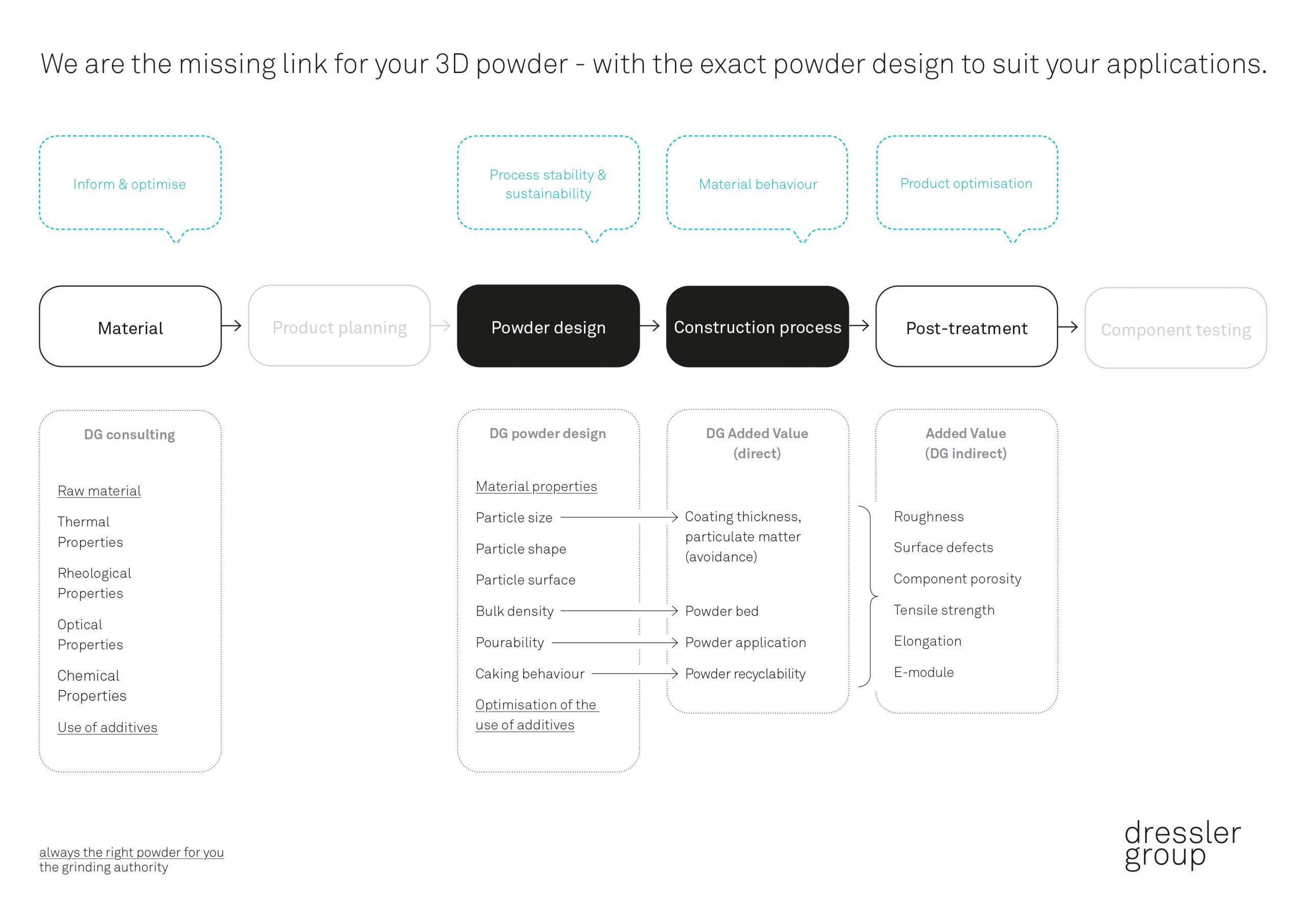

We are the missing link for your 3D printing powder– with precisely the right powder design for your applications.

Our powders give your 3D business a turbo boost – directly and indirectly, visibly and invisibly. Often the raw plastic only acquires its true value through individual grinding, the optional use of additives and customised powder design. This gives you competitive

- All your specifications met – and often even surpassed

- The processability of even the most difficult plastics

- Trouble-free processes thanks to optimum flow properties

- Consistent batch-to-batch quality, even on an industrial scale

- Maximum material, cost and energy efficiency

- Minimised cleaning requirements and machine downtime

- Minimised ecological footprint

- And much more besides

P.S.: We specialise in high-performance polymers (e.g. PEEK, PEKK), which we make printable in the first place using our patented Spherical Powder Technology (SPT) process.

Added Value

We inform

and optimise

For more

Process stability and

sustainability

Our contribution to improved

material behaviour

Impact on product optimisation

Material

Product planning

Powder design

Construction process

Post-treatment

Component testing

DG consulting

Raw material assessment, e.g. through material screening

Selection of optimal additives

DG powder design

Material properties

Particle size

Particle shape

Particle surface

Bulk density

Pourability

Caking behaviour

Optimisation of the

use of additives

DG Added Value (direct)

Coating thickness,

particulate matter (avoidance)

Powder bed

Powder application

Powder recyclability

Added Value (DG indirect)

Roughness

Surface defects

Component porosity

Tensile strength

Elongation

E-modul

Mission

We get the best out of your powder in terms of:

- Printability

- Powder purity

- Material and energy efficiency

- Adherence to specifications

Absolute customer focus

You are at the centre of what we do. We develop exactly the right powder for you – and you can only get that exact powder from us. Our mission: “To design the right powder for you, we need to understand your process.” That means we are involved in your processes from the very beginning. Together we develop individual solutions that not only meet current requirements, but also open up future market opportunities

Have we piqued your interest?

Then you are just one click away from greater performance.

Find out more about our 3D printing expertise – and about the Dressler Group as a whole – here.

Your contacts

Time to take the next step.

Get in touch with us. We look forward to hearing from you. Seize the opportunity to develop your future successes with us and avoid standing still.

Jan Dressler

Chief Executive Officer, Chief Innovation Officer

„We are a holistic system and process partner for our customers. We enable new customers to make a smooth initial entry into 3D printing and we help existing customers to expand their position – always with the utmost efficiency and minimised risk.“

Christian Manteuffel

Team Manager Sales

„More than 80 percent of all processes that we develop and test at our R&D facilities, the Innovation Lab and Technical Centre, go into series production. So we function like an external R&D department for many customers.“

Alexander Leis

Manager Sales

„We can get the maximum out of even the most difficult plastics – because our chemists, process engineers and plant constructors are constantly working in extremely close collaboration with our customers.“

Connect with us to stay informed.

Dressler Group is a family business. Absolute customer focus and a personal, trusting relationship are part of our DNA. Our experts work for your success as if it were their own – get to know them here.

Get in touch with us!

I may withdraw the above consents at any time by sending an email to datenschutz@dressler-group.com.

Fields marked with * are mandatory.